Fire Sprinkler System Backflow Protection

Fire Suppression Water Can Threaten Drinking Water Safety

Some buildings are equipped with automatic, water-based fire extinguishing systems. Most often, the water for these fire sprinkler systems is supplied through a connection to the community drinking water distribution system. There is no flow through a fire sprinkler system until there is a fire, so the water sits stagnant and degrades over time. The water supplier does not want any of this contaminated water to backflow into their system, and will require an appropriate backflow prevention assembly to be installed, tested and maintained.

Depending on the level of risk, the water supplier will require either a Reduced Pressure Principle Detector Assembly (RPDA) or a Double Check Detector Assembly (DCDA). These assemblies are composed of two backflow preventers: the main, which is sized for the full fire water flow requirement; and a small "detector" water meter on a parallel bypass designed to read unauthorized uses of water. The detector meter is fitted with a second backflow preventer of the same style as the fire line backflow. Both backflow preventers must be tested on an annual basis and maintained as necessary.

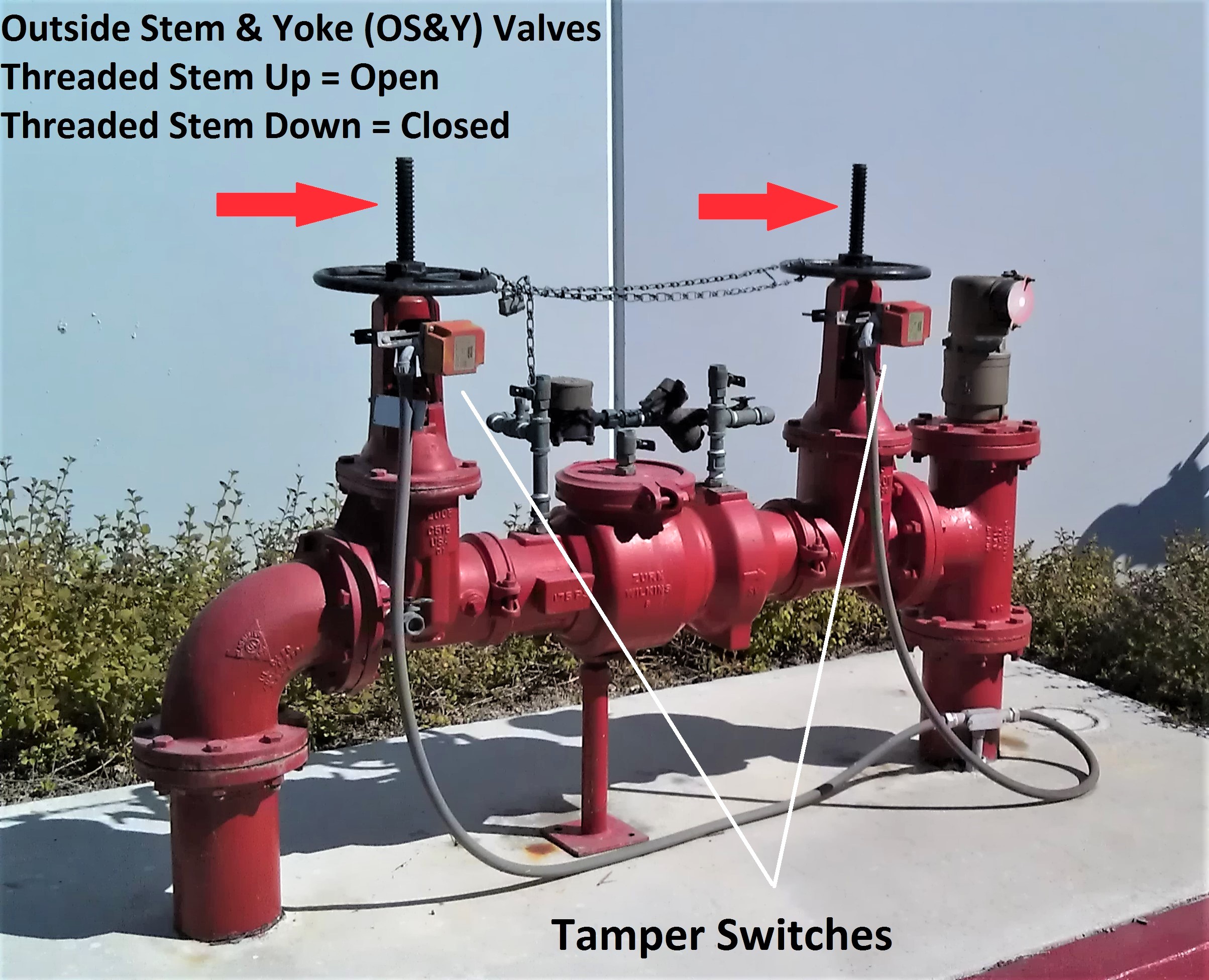

In order to reassure the fire department that the system is operational, the fire line backflow preventer shutoff valves are required to visibly indicate whether they are open or shut. Indicator valves are typically "Outside Stem and Yoke" (OS&Y) or Butterfly valves. They often, but not always, will have tamper switches which are hooked up to an alarm system. When the valve is operated, the tamper switch will signal the alarm monitor, who will contact the property owner and/or fire department. For this reason, we schedule testing and maintenance of fire system backflow preventers.