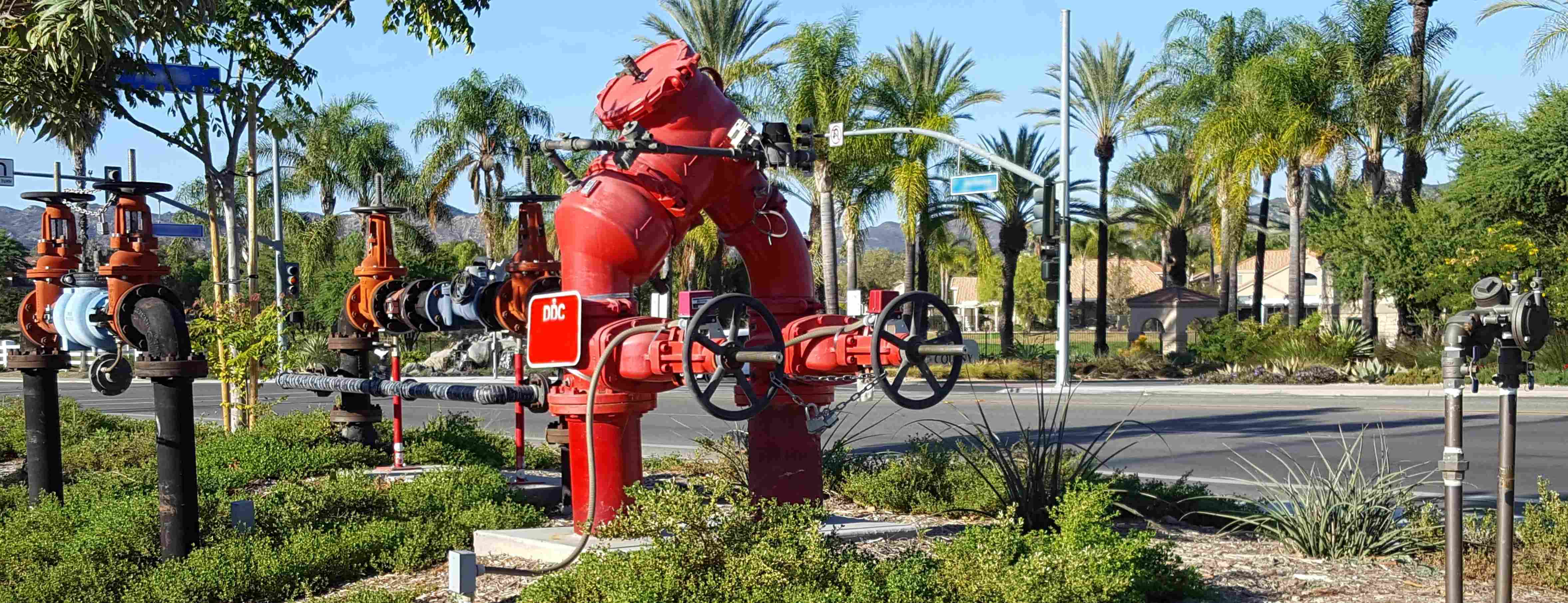

Water Delivery Systems

Why are Backflow Preventers important?

Delivering a Clean Water Supply

|

Clean water is a resource we have come to take for granted in America. It flows on demand out of the nearest faucet for drinking, cooking, bathing, and many other activities. But if not properly managed, this modern convenience becomes a serious public health threat. |

Defining the Risk

The term "backflow" means "the unwanted reverse flow of water and other substances into the safe drinking water supply". These unwanted substances in a user's system can threaten the health of other users connected to the distribution system (read: you and me). So in order to defend public health against this problem, backflow prevention assemblies are required wherever the water supplier identifies a risk to their distribution system.

The Uniform Plumbing Code lists many types of facilities, water uses and water using equipment that must have backflow protection before they can be connected to a public water supply. Water suppliers also conduct surveys to determine actual risk from a given facility. Read on to learn more.

Understanding Hydraulics

Positive pressure is used to deliver water from the treatment facility to the consumer. We might assume that the water always flows OUT from the supplier and IN to the consumer. This assumption would be wrong, as various factors can occur during normal system operation to result in water flowing opposite its normal direction. This normally is not a problem. That is, unless plumbing in an end user's system is connected to pollutants or contaminants. Then a reversal of flow can move those substances back through the user's plumbing and into the community water supply.

Backflow can occur because of a drop in the delivery pressure of the supply system. This pressure drop "pulls" water from the end user. Known as "backsiphonage", this might occur when an underground water line breaks, or during the fighting of a fire. Water is "pulled" from surrounding users to the point of greatest out-flow.

Backflow can also happen when the water pressure on the end user's side exceeds the pressure in the supply system. This high pressure "pushes" the water and anything in the end user's system back into the public delivery system. This potential exists when the end-user's plumbing is equipped with items such as pumps, boilers, elevated tanks, etc.

When either back-siphonage or backpressure occurs, pollutants and/or contaminants can backflow into the distribution system and will be delivered to nearby users when the next tap is opened.

What does a Backflow Preventer do and why must it be tested

Water suppliers must protect the quality of water up to the point of delivery to the end user. Backflow prevention assemblies are used to provide a separation between the delivery system and end user. Water users may also install backflow assemblies internally to protect themselves, their families, customers and employees from known hazards within their own properties.

Backflow assemblies are mechanical devices with specific design requirements. Most backflow assemblies are evaluated by the Foundation for Cross-Connection Control and Hydraulic Research at the University of Southern California. The Foundation's approval process involves stringent laboratory and field tests. Assemblies which successfully pass these tests are granted Approval. In all water districts of San Diego County backflow preventers must recieve USC approval in order to be used for protection of the water supply.

As with all things mechanical, break-downs are inevitable. Since backflow prevention assemblies are health safety devices, it is important to catch a break-down before it leads to an incident. Backflow assemblies must be field tested immediately after installation and at least once each year to ensure they are working properly. When a field test determines that a device is not working properly, the assembly must be repaired and retested. Field testing must be performed by a certified backflow prevention assembly tester, using an approved and properly calibrated test gauge.

A certified backflow tester is someone who has successfully completed a course of instruction in backflow prevention assemblies which includes theory, design, performance, testing, and maintenance. Upon successful course completion which includes both written and performance examinations, the backflow tester certification is issued. The certification for a backflow tester in San Diego lasts for 3 years and is issued by AWWA or ABPA. Some jurisdictions in the County also accept ASSE certification. Prior to certificate expiration, the tester must again successfully complete both written and performance examinations in order to keep their certification active.

Providing a clean and safe water delivery system free from objectionable impurities requires the cooperation of water providers, end users and certified backflow prevention assembly testers. Please join with us in helping to protect our drinking water system and keeping safe water flowing to our taps.